Although the answer to the question of what is adherence is known by those in the construction industry, it is not fully understood by many. Adherence, a concept important in almost every reinforced concrete construction project, is among the most essential elements of construction projects.

In our article, we will cover all aspects of the question of what is adherence, the answer to which is given simply as the bonding of different materials used in construction projects and their ability to act as a single substance.

Also, by reading our article titled, What is Concrete and What is in It? you can have detailed information about concrete, one of the most basic elements of construction projects.

What is Adherence?

It provides high durability by ensuring the adhesion of two materials to each other in adherence structures, which literally means adhesion. For example, in order for structures made of concrete and iron rods to become reinforced concrete, the rods must completely adhere to the concrete. Thanks to adherence, these two different materials stick together and become usable at the same time.

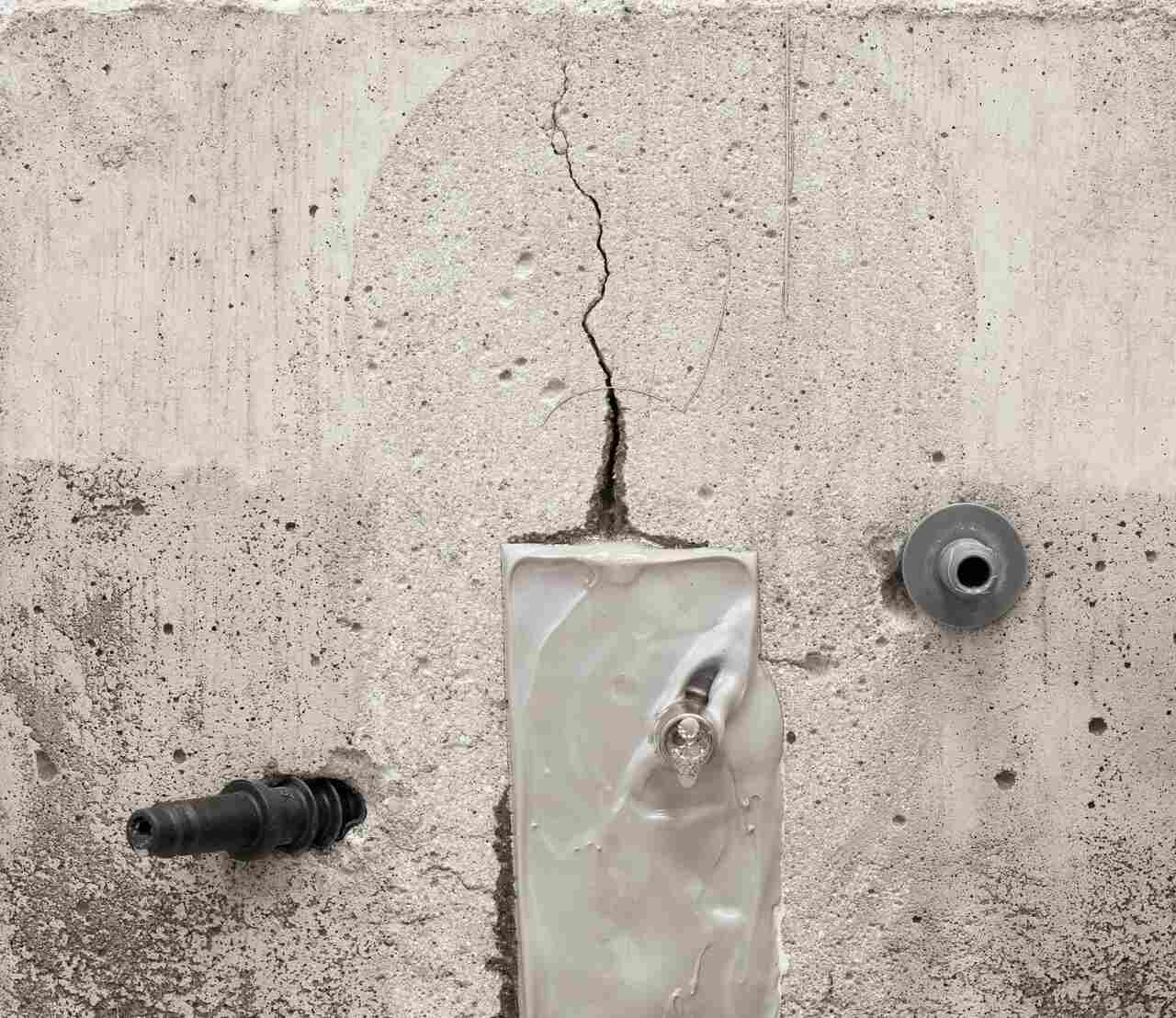

Reinforced concrete is applied to obtain durable structures for long periods in the face of natural disasters and many different external effects. In order to obtain reinforced concrete structures, concrete and iron bars called reinforcement must be stuck together. Adherence comes into play at this point, allowing the concrete and reinforcement to stick together and create a tension force between them.

The adherence that enables two different materials to stick and work together does not occur only between concrete and reinforcement. It is also used in different areas of construction projects, such as the adhesion of concrete to the aggregate used in cement production. The adherence, which is obligatory for a building project to become reinforced concrete, is used in all building projects today.

What is an Adherence Increaser?

When the adherence calculation is made in construction projects, the desired result may not always be obtained. Adherence-increasing methods, which are widely used in the construction industry, provide the necessary adherence to increase durability in structures where the strength is not sufficient.

At this point, many different adherence increasing methods are used:

- Use of ribbed reinforcement

- Adherence increasing additives

- Use of transverse reinforcement

- Raising the concrete grade

The methods listed above provide the desired results in adherence calculation. The most ideal adherence force is obtained with increasing methods that enable the durability of the structure to reach the required level.

Why is an Adherence Increaser Important?

As we mentioned at the beginning of our article, adherence is one of the most important factors to be considered at the point of turning a structure into reinforced concrete. If the adherence, which is directly proportional to the structural strength, is not applied correctly, it can lead to bad results in the long run.

Many fault lines in the geography of our country have increased the importance of paying attention to durability in construction projects. Many factors affect the durability of a structure, from the quality of materials used in construction, to lack of supervision and incorrect technical practices.

Therefore, in order for the building to carry its load safely to the ground, each different material contained in the building must move in unity. Thanks to the flexibility and rigidity provided by the ideal adherence, the structures become durable no matter how severe the load and pressure they may encounter.

What are the Adherence Increasing Methods?

As we mentioned before, the use of ribbed steel is an adherence-increasing method. At the same time, adherence-increasing additives also contribute to a higher adhesion strength of the applied surfaces. Thus, the increased adherence ensures that the durability of the structures reaches the ideal level.

Increasing the concrete class used is among the preferred methods to increase adherence. As the concrete class increases, adherence also increases. For example, the adherence difference between C40 and C50 concretes is quite high. Transverse reinforcement, which is another adherence-increasing method, also increases adherence.

One of the other methods in concrete is adherence-increasing additives. Additives applied to surfaces that are free from all kinds of dirt, oil, rust, and dust increase the adherence of mortar, plaster, and screeds and provide waterproofing. Waterproofing and Adherence Increasing Liquid Admixture - LATEX is one of the most effective adherence insulation additives with its different usage areas from interior and exterior plasters to screeds.

The advantages of adherence-increasing additives are:

- While adhesion-increasing primers bond two different materials together, they also provide environmental solutions by affecting energy savings in building projects.

- They contribute to insulation by preventing water loss in plasters. They offer environmentally friendly comfort by contributing to air conditioning.

- They are also used indoors, preventing the swelling of applications such as plaster and paint.

- Thanks to its practical application, they save time and labor.

- They protect the equipment against moisture and humidity.

- They show high resistance to salts used in frost removal applications.

- They adhere perfectly to concrete and steel.

- Their mechanical strength is extremely high.

How to Apply Adherence Increasers?

Before starting the application of adherence-increasing additives, the surface preparation of the floor to be applied must be done. The surface of the floor, which is cleaned of all kinds of dirt, rust, and foreign matter, should be saturated with water, but excess water should not be left on the surface. Steel surfaces, on the other hand, should be cleaned of elements such as dirt and rust that reduce adhesion, and should be made ready for application of adherence increaser by sanding.

For example, when applying Corrosion Protection and Bonding Agent Mortar - REPAMERK 325, approximately 6 liters of water is used for 25 kilograms of increaser. Water and REPAMERK 325 should be mixed and left to rest for 4 minutes and mixed again for another 30 seconds and applied with a brush, roller, or spray system.

If an application is to be made to prevent corrosion, the prepared mixture is applied to the iron reinforcement with a brush in at least two layers. The first coat is applied to the cleaned reinforcement with a thickness of 1 mm by brush, roller, or spraying. After about 3-4 hours, the second layer is applied. Concrete surfaces and reinforcements are covered with repair mortar 30 minutes after the application of the second layer, which should be of similar thickness.

In the application as a primer, the prepared mixture is applied with a brush or spray system so that the thickness does not exceed 1 mm. Concrete surfaces are covered with repair mortar 30 minutes after the application is completed.

We have come to the end of our article in which we seek the answer to the question of what is adherence. As Baumerk, the construction chemicals specialist, in our article, we examined adherence, which is one of the most important elements of increasing durability in construction, in all details.

Also, you can find all the products you need to increase the strength and durability of your construction projects among the construction chemicals and waterproofing membranes in the Baumerk product portfolio. At the same time, you can contact Baumerk, who has a well-equipped technical team, for all your technical questions.