When asked what is concrete, an image appears in everyone's mind. But to evaluate from a technical point of view, concrete is a kind of mixture. As Baumerk, the construction chemicals expert, we will share the details that are useful to know about concrete in this content.

What is Concrete? What Does It Do?

Concrete is one of the most essential materials of construction. Concrete, which is an important factor to solid building, affects the strength of the structure according to the type and quality of the materials it contains.

Basically, concrete is obtained by a homogeneous mixture of cement, water, aggregate, and auxiliary chemical additives using a certain production technology. The aggregates in its content are called fine and coarse aggregates and are generally materials such as sand, crushed sand, and gravel.

These materials must be combined with water and a binder to form concrete. This binding material is usually cement. Except for the cement, it is seen that asphalt and polymer are used as binders in concrete.

Concrete is named according to the type of binder used. For example, if concrete contains Portland cement, then it is called Portland cement concrete; if concrete contains asphalt, it is called asphalt cement concrete; if concrete contains polymer as a binder, so it is called polymer concrete.

How to Make Concrete?

Concrete can be sent to construction as ready-mixed concrete or can be made through concrete mixers in construction sites. The producing company produces ready-made concrete according to the technical values and specifications requested by the customer.

The company determines the ratio of cement, water, aggregate, and additives in the production formula, produces the concrete homogeneously in the concrete plant or with the help of mixers, and then transfers it to the constructions with truck-mixers. This mixing process is carried out manually in concrete mixers.

What Are Concrete Admixtures And Why We Use Admixture in Concrete?

Concrete admixtures are organic and inorganic materials used for concrete in addition to water, binder and aggregate, which are the main components of concrete. Concrete admixtures can increase strength, delay or accelerate hardening of concrete, provide water repellency, and prevent freezing. In other words, the desired properties of concrete can be achieved thanks to concrete admixtures.

Concrete admixtures, which will be added to the formula, are selected according to aggregate properties, concrete class, water/cement ratio, and ambient temperature. Concrete is poured while it is fluid, hardens by curing over time, and gains final strength.

Raw materials and their proportions in concrete affect the final strength and performance of concrete. Concrete may lose its strength over time after drying as a result of chemicals and external factors. So it can not carry the load, it may collapse or become unusable. To prevent this, the raw material ratios of the mixture should be adjusted correctly and the concrete should be strengthened with suitable concrete admixtures.

Contact with water is the best known and most likely situation that can cause performance loss in a structure. Concrete is constantly exposed to groundwater from the foundation, rainwater from the roof, and domestic water.

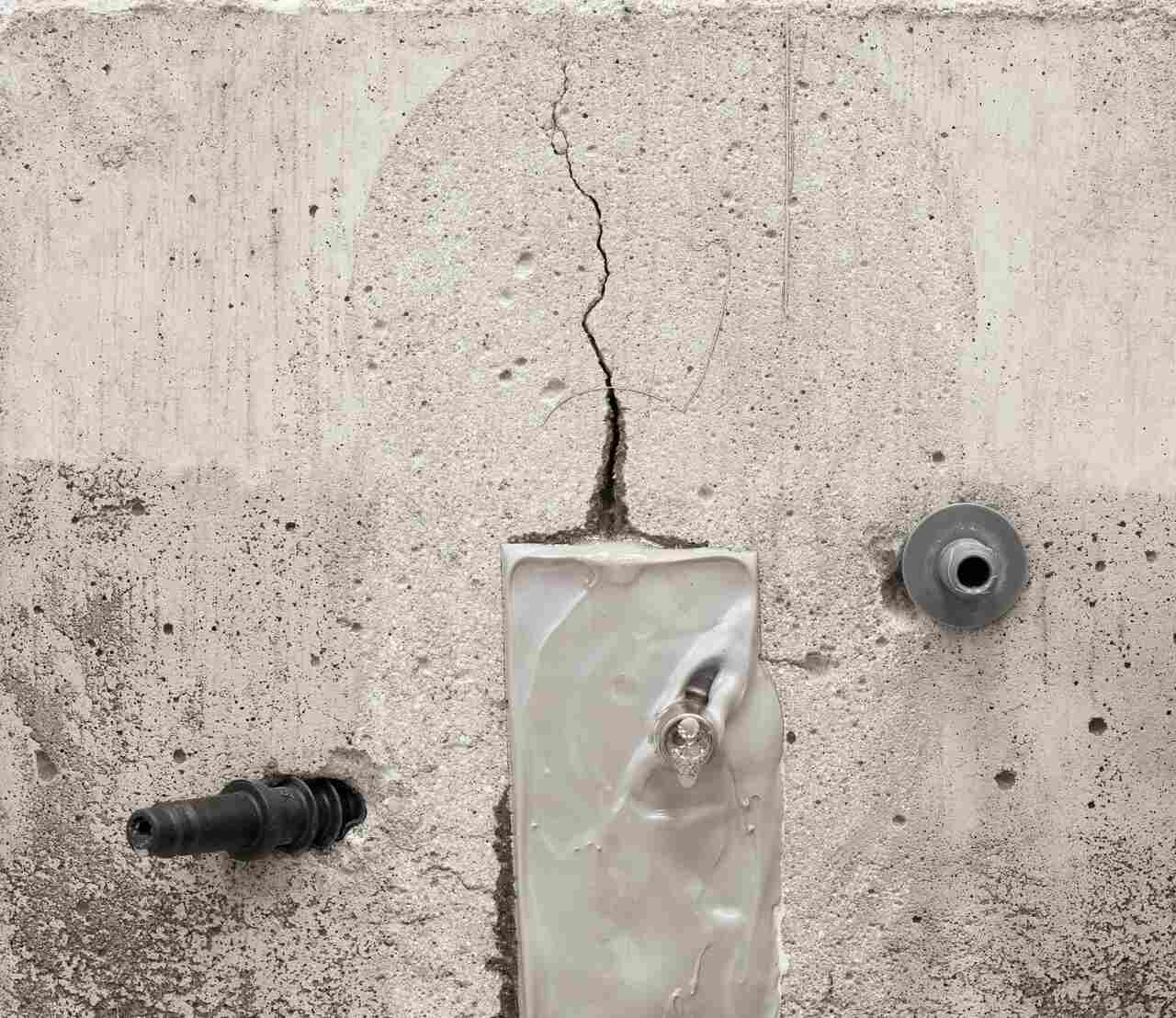

The minerals in the water react chemically with the concrete and adversely affect the water impermeability of the concrete, then cause rust and corrosion by forming cracks. As a result, strength and durability losses occur.

To prevent such negative effects, possible short and long-term durability problems should be considered while designing concrete. Concrete should be made waterproof with concrete admixtures.

Which Concrete Admixture Material Should Be Preferred?

Concrete admixtures are produced in various options according to the properties to be added to the concrete. Also, there are concrete admixtures that can be used during concrete production as well as can be used for finished ready-mixed concrete.

For example, in plaster, screed, and concrete tasks when water and moisture impermeability is required, powder and liquid concrete admixtures with water repellent properties are one of the most preferred ones. These materials are added to fresh cement and give the concrete water impermeability.

Besides the admixtures that provide water impermeability for concrete and mortar, admixtures that create a crystalline effect also provide a long-lasting water impermeability even if the concrete is in contact with water. Crystalline admixtures react with the moisture inside the concrete, forming crystal structures that do not dissolve in the capillary cracks and pores in the concrete, making the concrete permanently waterproof.

After the concrete is poured and hardened, there are ready-to-use admixtures that can be applied on the concrete and fill the capillary spaces and pores by reacting with the cement and sand in the concrete and mortar mixture.

In addition to water impermeability, chloride-free liquid concrete admixtures, which accelerate the set of concrete and give concrete resistance against freezing, are also highly preferred products in construction.