Waterproofing is one of the most significant parts of the construction process. The developments used for this purpose advance in parallel with the improvements in the construction industry. Baumerk, which always follows the innovations in the sector closely and focuses on developing its product range, continues to be your solution partner in the latest products related to waterproofing.

Waterstop tape types and waterstop tape application is one of the important parts of waterproofing. If you plan to apply waterstop tape in your construction and you are researching the most ideal waterstop tape types for this; we recommend you read this article!

What Is Waterstop Tape?

Before we get into the subject of waterstop tape types and their application, let’s get to know this material better. Waterstop is a concrete building element that aims to prevent the passage of fluids when they are constantly embedded and flowing into concrete joints. It protects the structure against damaging elements such as water, mud, and moisture that can be encountered in any construction. In this sense, waterstop tape applications are an indispensable part of the construction process.

Where is the Waterstop Tape Used?

Waterstop tape types and waterstop tape applications are on the agenda of the field professionals. However, if you have just started research in this area or if you are wondering exactly where these applications will be applied in your construction, we would like to enlighten you on this matter. Waterstop tapes are used to prevent liquid or liquid-containing structures, foundation walls, tunnels, and similar concrete structures from passing through the joints. Other application areas are:

- Dams

- Tunnels

- Regulators

- Water Tanks

- Waste Treatment Units

- Swimming pools

- Channels

- Bridges

- Metro Stations

- Sewerage Systems

- Irrigation Channels

- Ports

- Transport Tunnels

- Hydroelectric Power Plants

- Air Ducts

- Protection Walls

- Floor

- Industrial Buildings

Qualities of Waterstop Tapes

Knowing the properties of waterstop tapes, which are indispensable for insulation applications in the constructions, will help you make the right choice. It is important to make sure that your waterstop tape has these qualities when choosing waterstop tape types. We can summarize the features required for an ideal waterstop tape as follows: Waterstop tape types have high tensile strength.

- These tapes have superior elongation due to their usage area.

- Quality types of waterstop tapes generally have excellent internal elasticity and sealing.

- They are highly resistant to acids, ozone, seawater, and even diesel.

- They are extremely resistant to alkalis, chlorinated water, and other water-based chemicals.

- As with metal or rubber, it is sensitive to fatigue deterioration.

-

They are of high quality and meet the industry standard.

- Correctly selected waterstop tapes do not discolor the concrete.

- They have no electrolytic effect on the surrounding metals.

- They can withstand hydrostatic pressure.

- They can be heat welded together with electric welding machines.

- They can resist the expansion and contraction movements of the joints.

- They are compatible with any deviation or displacement resulting from temperature change or different placement of the foundation.

- They are easy to assemble by connecting the outer flanges of the PVC waterstop to a reinforcing bar.

- PVC compound has unique properties such as ease of use and low-temperature flexibility.

- They are supplied in rolls that are easily transportable, flexible, and can be bent around corners or curves as required.

Different Types of Waterstop Tape

The waterstop tape types ideal for you are included in this list. You can choose from the most suitable types waterstop tapes, considering your business needs and the properties of your construction. Since joints in a concrete structure penetrate the water, they are the most vulnerable areas for leakage and cracking. In most structures this leads to mold and fungal growth and can affect the integrity of the structure. There are several waterstop areas for construction joints, each with different strengths and weaknesses and suitable for certain applications. Here are some of the most common ones we've compiled about…

PVC Waterstop Tapes

PVC waterstop tape; is extruded from an elastomeric plastic material containing high-grade polyvinyl chloride, special resin, and some chemical additives such as plasticizers and stabilizers. The PVC waterstop tape embedded in concrete joints acts as a continuous waterproof diaphragm to prevent any liquid leakage in building joints exposed to hydrostatic pressure. It is designed for expansion or contraction joint; It can accommodate lateral and transverse stretching movements that allow it to accommodate dynamic connections. PVC is used to make construction joints waterproof on both sides of the joint to form a physical barrier. Various widths, thicknesses, and sizes are available to fit almost all construction joints. The advantage of PVC waterstops is that they can be installed in almost any condition, including rainy and wet conditions. They also tend to last for a long time. The difficulty arises during the installation process. It takes time to properly insert PVC into the hinge and can easily be damaged during concrete pouring.

How to Apply PVC Waterstop Tapes?

After obtaining information about the types of waterstop tapes, it is time for the application of waterstop tapes. In general, proper waterstop tape applications determined by the performance of preventing waters and other waterborne chemicals. Any deviations and misalignments should be avoided. The best installation way is to fix the PVC waterstop tape to the perimeter steel frame. So, you can consult Baumerk expertise for easy installation.

So how are the PVC waterstop tape applications performed? To make sure that the w waterstop is correctly and properly placed in the concrete, it is fixed using a slide mold or other suitable method. Waterstop tape is placed exactly in the middle of the connection. It is necessary to thoroughly vibrate the concrete around the waterstop to eliminate gaps or honeycombs and ensure that concrete is effectively attached to the water retainer rods.

The addition can be accomplished by softening the ends of the waterstop tape over an indirect heat source to a melting point of 200 ° C ± 10 ° C. Thermostatic controlled, Teflon coated welding irons are recommended. When the plastic begins to melt, the ends are directly aligned and must be held firmly in position for about 20 seconds until the plastic cools.

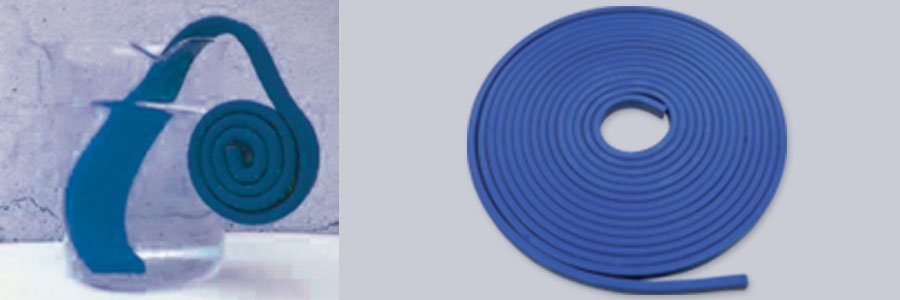

Bentonite-Based Waterstop Tapes

Bentonite, which falls into a hydrophilic waterstop system category, is a swelling bristle compound that expands up to 16 times when in contact with water. This helps create a sealing gasket in concrete joints and fill small areas in concrete, such as cracks and voids. However, as a hydrophilic waterstop, this feature also means that it is very important to keep the bentonite dry and pour concrete immediately after application. If bentonite is exposed to early moisture, it can damage the joints and weaken the concrete around the joint. Besides, bentonite has limited flexibility in which the water trap can expand and contract; they can eventually wear out.

How Are Bentonite-Based Waterstop Tapes Applied?

Let us get into the application of this type of tape… First of all, we can say that concrete-based waterstop tapes scan be applied quite easily. These tapes are easily applied even when they are too dull. It will be enough to bring it side by side to what you want to do additional joining. Thanks to the fast application, even in a single-person environment, more than 130 meters of application can be done within an hour. The fact that one person can apply a tape makes it preferred especially by people working alone. It can be used safely as it does not mix with drinking water. For the application, you can start by separating the bentonite-based waterstop tape of the desired length from the roll. The process is almost complete after the exposed surface is glued to the concrete. The placement process is carried out by using a primer where necessary and paying attention that every point of the tape is in contact with non-smooth surfaces. Then silicone paper is peeled off and the concrete is poured carefully. The application is completed in this way.

Acrylic Polymer-Based Waterstop Tape

Now, it is time to explain another product that comes to the foreground regarding waterstop tapes types and their application. Acrylic Polymer Based Waterstop Tape, is one of the indispensable products of the constructions. Acrylic polymer-based waterstop tape, which is also included in the Baumerk product range, is an easy-to-apply, durable product that gives desired results easily. This band, which is called Swellband A in the market, has many advantages that it gives the user. First of all, acrylic polymer-based waterstop tape is non-toxic. With this feature, it is a product that is respectful to nature and humans. Besides, it provides ease of use. It gives good results even in fine workmanship and detailed work. It has excellent adhesive power. This increases its permanence and comfort after application.

These tapes have high adhesion and peel strength. In this sense, they are quite cost-effective. Additionally, acrylic polymer-based waterstop tape is suitable for excellent coating performance and transfer coating. When taken from the right manufacturer and applied correctly, it gives permanent and perfect results.

How to Apply Acrylic Polymer-Based Waterstop Tape?

Acrylic Polymer Based Waterstop Tapeis very easy to apply. It is one of the most effortlessly applied among the types of waterstop tapes. To do this, it is necessary to cut enough of Swellband A first. Then this cut amount is dissolved, and the exposed part is combined with concrete. There is a point you need to pay attention to here. It is important to leave a gap of at least 75 mm on the edge of the concrete coating. After the tape is glued, it is pressed tightly. If you are going to do your application vertically or head-to-head, you should apply the appropriate primer before the tape and wait for about 15 seconds. While applying the Acrylic Polymer-Based Waterstop Tape between the waterstop applications, it is necessary to make sure that the surface is completely integrated with the waterstop tape. This is an important point to be taken into consideration especially on partly uneven, recessed, and protruding surfaces. The ends of the strips must not overlap and come side by side or end-to-end if you are going to progressively add. After placing the tape, the silicone paper on it must be removed and carefully poured on the concrete.