Many people are curious about the mysterious world beneath our feet, where hidden passages connect distant places and provide essential transportation and infrastructure networks. Underground tunnels are engineering marvels that provide seamless travel and logistical support.

However, the construction and maintenance of these underground lifelines brings its own challenges. One of these challenges is the application of tunnel waterproofing, a crucial process to protect these vital conduits from water ingress.

In this article prepared by Baumerk, construction chemicals specialist, we take an in-depth look at tunnel waterproofing, exploring its importance, methods, and materials used in tunnel waterproofing applications.

What is Tunnel Waterproofing?

Tunnel waterproofing is a crucial process that protects underground passageways from the relentless power of water. As underground arteries that facilitate transportation and infrastructure networks, tunnels are constantly at risk of water ingress, which can lead to structural damage, corrosion, and compromised safety. To combat these challenges, tunnel waterproofing involves the application of specialized techniques and materials to create an impermeable barrier that prevents water from seeping into the tunnel.

Using a variety of innovative methods, tunnel waterproofing ensures that these hidden lifelines are long-lasting, functional, and reliable.

What Are the Types of Tunnel Waterproofing?

Waterproofing a tunnel is a complex endeavor that requires careful planning, engineering expertise, and the use of appropriate methods. Let us now begin to examine the various techniques used in tunnel waterproofing.

-

Membrane Waterproofing

One of the commonly used methods for tunnel waterproofing is the application of waterproofing membranes. Membranes act as a barrier, preventing water from seeping into the structure. Polymer Bituminous Membranes with APP Additive, Designed for Bridges and Viaducts, specially produced by Baumerk for tunnels and bridges, stand out with their long life as well as providing high-level insulation.

-

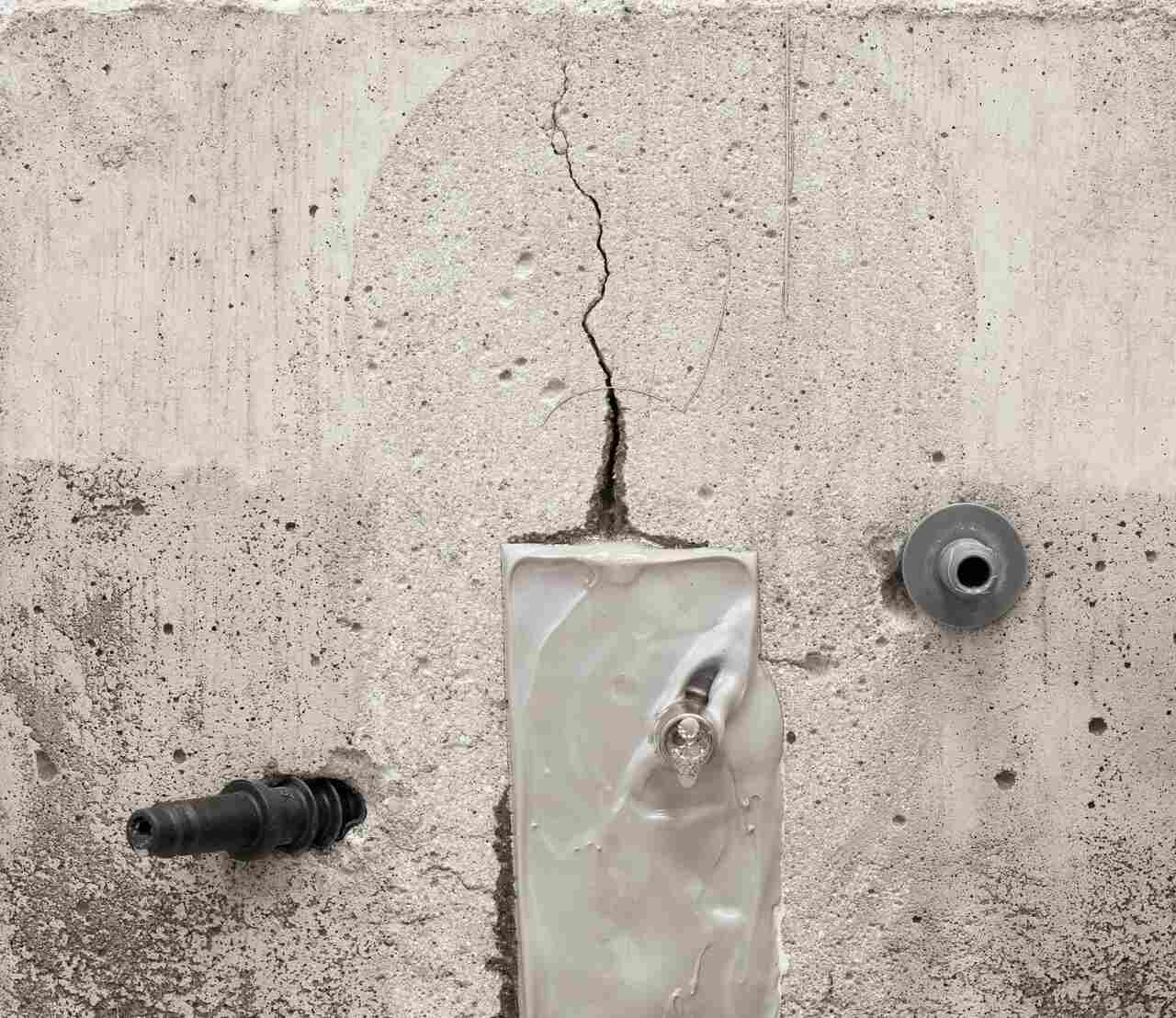

Injection Waterproofing

Injection waterproofing is another technique used to protect tunnels against water ingress. This method involves injecting specialized materials into cracks, joints and crevices in the tunnel structure. The injected materials, usually grouts or resins, penetrate the voids and form a watertight sealing structure, strengthening the tunnel's resistance to water pressure. Injection waterproofing is particularly effective in sealing small leaks and strengthening the structural integrity of the tunnel.

Reinforcing Purpose, Epoxy Based Injection System - EPOX IN 25, specially produced by Baumerk, stands out as one of the most reliable products when injection waterproofing is preferred in tunnel insulation.

-

Cement Based Waterproofing

Cementitious waterproofing is a versatile method widely used for tunnel waterproofing. It involves applying a cement-based coating or mortar to tunnel surfaces. This coating forms an impermeable layer, preventing water ingress and providing durability. Cement-based waterproofing is suitable for both new projects and for sealing existing tunnels. It offers excellent resistance to water pressure and can be further improved by adding additives for better performance.

Cement Based, Crystalized Waterproofing Material - CRYSTAL 25 in the Baumerk product range offers you the right solution for all construction projects with its perfect insulation.

What are the Tunnel Waterproofing Steps?

Tunnel waterproofing involves a series of steps to ensure a comprehensive and effective seal against water ingress. While the specific steps will vary depending on the project and the waterproofing method chosen, a general outline of the process is provided below:

-

Site Assessment and Preparation

-

Conduct a thorough survey of the tunnel site to assess geological conditions, water table levels and potential sources of water ingress.

-

Identify any existing cracks, joints or areas of concern that may require special attention during the waterproofing process.

-

Prepare tunnel surfaces by cleaning and removing loose debris and provide a suitable substrate for waterproofing materials.

-

Surface Preparation

-

Repair visible cracks or defects in the tunnel structure using appropriate repair techniques and materials.

-

Smooth uneven surfaces and remove protrusions that may interfere with the proper application of waterproofing materials.

-

Selection of Waterproofing Method

Based on the site assessment, select the most appropriate waterproofing method or combination of methods from the techniques listed above.

-

Applying a Waterproofing Membrane

-

If membrane waterproofing is selected, apply the selected waterproofing membrane to the tunnel walls, roof and/or floor.

-

Ensure proper adhesion and overlapping of the membrane layers following the manufacturer's instructions.

-

Repairing Cracks and Joints

-

If injection waterproofing is part of the plan, inject special materials (e.g. grouts, resins) at these points to seal cracks and joints and reinforce the tunnel structure.

-

Follow the specific injection procedures and ensure that the targeted areas are properly penetrated and filled.

-

Application of Cementitious Waterproofing

-

If cementitious waterproofing is selected, apply a cement-based coating or mortar to the tunnel surfaces using appropriate tools and techniques.

-

Pay extra attention to areas prone to water infiltration to ensure that the cementitious layer is evenly coated and of appropriate thickness.

-

Quality Control and Testing

-

Perform rigorous quality control inspections throughout the waterproofing process to check for correct application, adhesion, and coating.

-

Perform necessary tests, such as water spray tests or hydrostatic pressure tests, to assess the effectiveness of the waterproofing system.

-

Maintenance

-

Regularly monitor the tunnel for signs of water ingress, such as leaks or moisture, and address any problems detected immediately.

-

Implement a maintenance plan, including periodic inspections and necessary repairs to ensure the long-term performance and durability of the waterproofing system.

By following these steps and adapting them to specific project requirements, engineers can successfully waterproof tunnels, protect them from the damaging effects of water and ensure their longevity and reliability.

We have come to the end of our article where we have provided detailed and valuable information about tunnel waterproofing. To summarize, various methods such as membrane waterproofing, injection waterproofing, and cementitious waterproofing offer valuable solutions to reduce the risks of water leakage. In addition, choosing the right tunnel lining materials ensures the structural integrity and longevity of these vital transportation and infrastructure networks.

As engineers continue to push the boundaries of tunneling technology, advances in tunnel waterproofing methods and materials are expected to improve the safety, durability and resilience of underground tunnels. By combining innovative solutions with rigorous planning and maintenance practices, we can ensure that these mysterious wonders will continue to serve us reliably and connect our world in unseen ways for generations to come.

As Baumerk, we offer you the most reliable solutions with our waterproofing membranes and construction chemicals. You can easily find the solution you need by browsing these products! You can also contact Baumerk for all your needs in your projects.

Finally, Let us remind you that you can also take a look at our article titled What Is Crystalline Waterproofing? 5 Benefits of Crystalline Waterproofing and our blog with informative content about the construction world!