Epoxy floor coatings are known for their durability and long service life. They are made through a chemical reaction between epoxy resin and hardener components, creating a strong, resistant, and smooth surface. One of the primary areas of application for this durable material is in industrial facilities.

As Baumerk, a leading expert in construction chemicals, we have shared the details about the use and advantages of industrial floor coatings with you!

Where Are Epoxy Floor Coatings Used?

Epoxy flooring is commonly applied in areas with high foot traffic. It is used in public buildings, factories, industrial warehouses, garages, and hospitals. Due to the aesthetic and stylish appearance it provides, epoxy coatings are also increasingly being used in interior spaces.

The main areas of application for epoxy floor coatings in industrial settings include factories, workshops, warehouses, and industrial plants. The reason for choosing epoxy in industrial facilities is its ability to withstand both chemical and mechanical stress. One of the key characteristics of epoxy flooring is its chemical resistance, which is essential for industries, laboratories, and workshops. Let's take a closer look at some of the areas where epoxy flooring is applied.

-

Food Industry

Food facilities, especially for employee safety, are coated with epoxy-based materials. Slip-resistant epoxy coatings are used to prevent employees from slipping and to reduce the risk of injuries. For example, in these facilities, EPOX FL 600 W, a water-based and epoxy coating, is applied in high-traffic areas.

-

Manufacturing and Commercial Facilities

Epoxy coatings are also used in production and commercial facilities with concrete floors to increase the wear resistance of the concrete surface. Typically, dry mix surface hardeners are used to enhance dust-proofing and improve wear resistance against impacts. EPOX FL 700, an epoxy-based topcoat, is also effective in preventing dust penetration and resisting impact damage on concrete surfaces.

-

Hospitals and Healthcare Facilities

Hospitals and other healthcare facilities require hygienic and sterile floors, walls, and ceilings, which is why epoxy is preferred. The smooth, bacteria-resistant, dust-resistant, and durable surface provided by epoxy flooring is suitable for areas with high foot traffic. EPOX FL 500 is a material with isolation and hygienic properties, perfect for application in both concrete and cement-based surfaces in healthcare settings.

-

Food and Beverage Facilities

Epoxy coatings are used to reduce slip risks and create a hygienic environment in food production areas. Food production facilities prefer epoxy coatings for their hygienic and decorative properties.

-

Warehouses and Logistics Facilities

In factories and facilities with medium to heavy human and load traffic, wear and impact damage may occur. The primary material used to prevent such issues is epoxy floor coatings. EPOX SL 800, a self-leveling epoxy product, is applied on both concrete and cement-based surfaces, offering high chemical and mechanical resistance.

In such environments, it is common for various chemicals to spill, exposure to chemical vapors, high-impact and intense friction stresses to occur. Therefore, epoxy flooring is the preferred solution to prevent these issues, providing a durable and long-lasting surface for industrial processes and heavy traffic areas.

Advantages of Industrial Epoxy Floor Coatings

Epoxy material stands out from other floor coatings due to its water resistance, aesthetic appearance, and extreme chemical resistance. Particularly in industrial facilities with wet areas, epoxy coatings prevent the penetration of water and other liquids due to their low permeability.

There are various reasons why epoxy flooring is used in industrial and manufacturing areas. With its numerous advantages, epoxy coating enhances the durability and aesthetics of floors. Here are the key features of epoxy floor coatings:

-

High Durability

Epoxy coatings resist chemicals, bacteria, and microorganisms, providing a hygienic environment. They show high resistance to acids, bases, oils, fuels, and various solvents. This makes epoxy coatings ideal for industrial plants, laboratories, and food production areas. Mechanically, they also exhibit high impact resistance, wear resistance, and the capacity to support heavy loads.

-

Adds Gloss to Surfaces

Epoxy coatings provide a smooth and glossy finish to the surface, which spreads evenly due to its self-leveling property. This feature makes movement easier in industrial areas, and facilitates the movement of mechanical vehicles and transportation.

-

Quick to Apply and Dry

Epoxy floor coatings can be applied quickly, saving time. They also dry rapidly, becoming ready for use without disrupting industrial workflows.

-

Supports Sound Insulation

After the application of the coating, a smooth surface is created, supporting sound insulation. This feature is particularly useful in noisy industrial environments, improving working comfort.

-

Easy to Maintain and Clean

With its non-porous structure, epoxy coating provides a smooth and impermeable surface. It does not trap dust or stains, and cleaning is extremely easy. This advantage is crucial in industrial areas where hygiene is critical.

-

Creates an Aesthetic and Modern Appearance

One reason epoxy floor coatings are used in modern interiors is their ability to create an aesthetic appearance. The surface can be decorated with various colors and designs according to surface characteristics and aesthetic preferences.

You can read our article titled "What is Epoxy? What Are the Properties of Epoxy Material?" where we discuss the benefits of epoxy material in more detail.

How is Epoxy Flooring Applied in Industrial Facilities?

For decorative and durable coatings, epoxy flooring requires surface preparation. The application process for epoxy flooring, including surface preparation, is as follows:

-

Remove chemicals, oils, and dirt from the base layer of the surface.

-

Choose a surface preparation method (diamond grinding, milling, steel ball, or sanding).

-

Apply an epoxy primer.

-

Apply a second coat of primer.

-

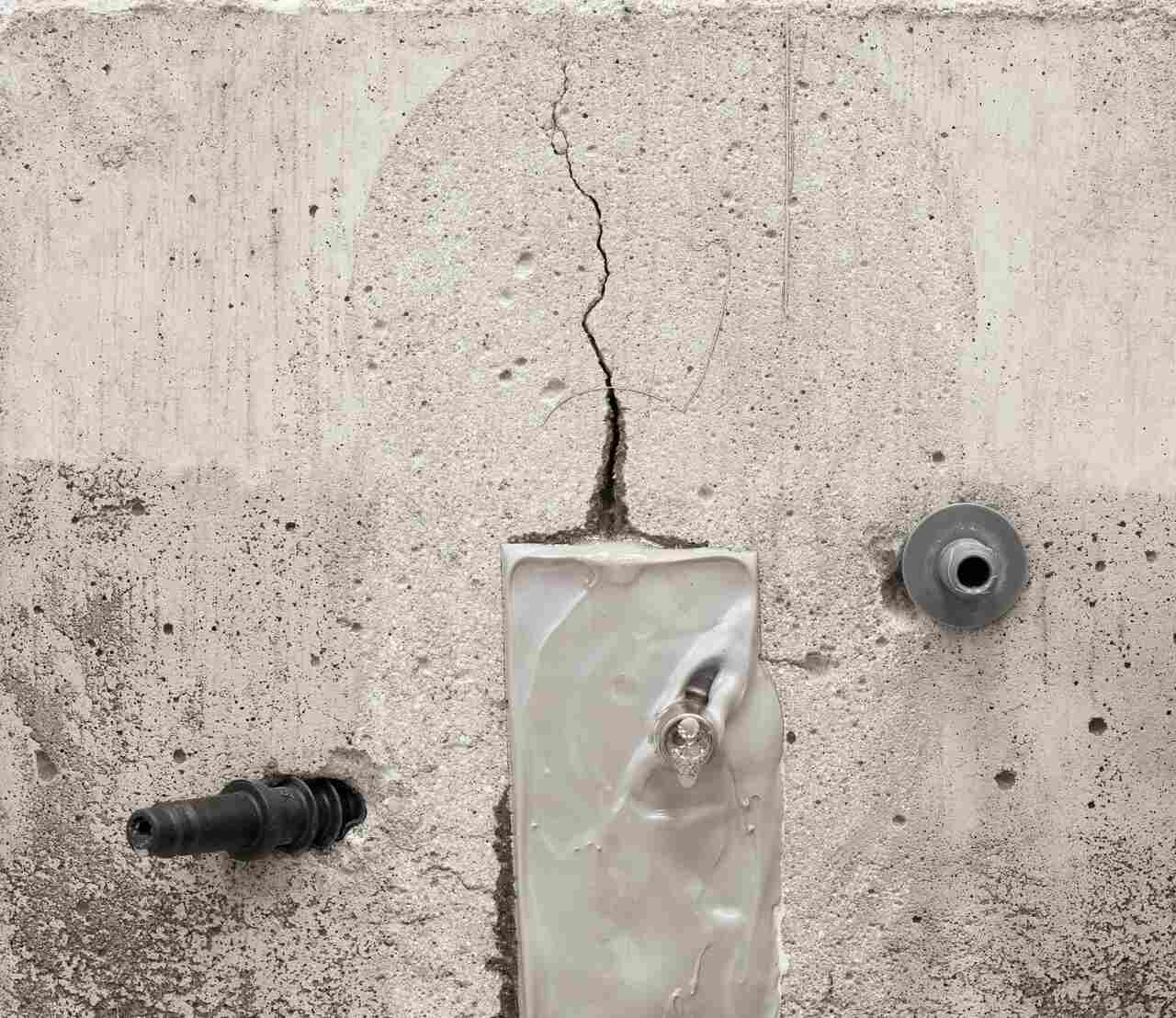

Fill cracks and holes with epoxy filler.

-

Apply self-leveling floor coating material using a trowel or screed to the prepared surface.

-

Apply a second coat of floor coating and perform sanding and filling.

-

Apply the final coat using a trowel or roller.

By using self-leveling, easy-to-apply epoxy-based floor coatings, a clean and aesthetic surface can be achieved.

As with other construction chemical applications, epoxy flooring should be done professionally. Otherwise, problems such as cracking, bubbling, and water leakage may occur. Typically, after a professional epoxy flooring process, the surface becomes ready for use within a week.

We have shared the advantages and application details of industrial epoxy floor coatings. You can explore all the construction chemicals suitable for your floor’s needs in the Baumerk Construction Chemicals category.