Shrinkage, in short, is the reduction in volume and size of concrete due to the loss of water inside the mix. So, what causes this volumetric change in concrete known as shrinkage? Shrinkage results from various factors and manifests through contractions and cracking. As Baumerk, experts in construction chemicals, we’ve detailed what shrinkage is and why shrinkage cracks form.

What Is Shrinkage in Concrete?

Concrete shrinkage refers to the loss of moisture within concrete. The liquid in the concrete may evaporate over time or be consumed during chemical reactions. Volume loss can also occur due to the disappearance of capillary water in voids.

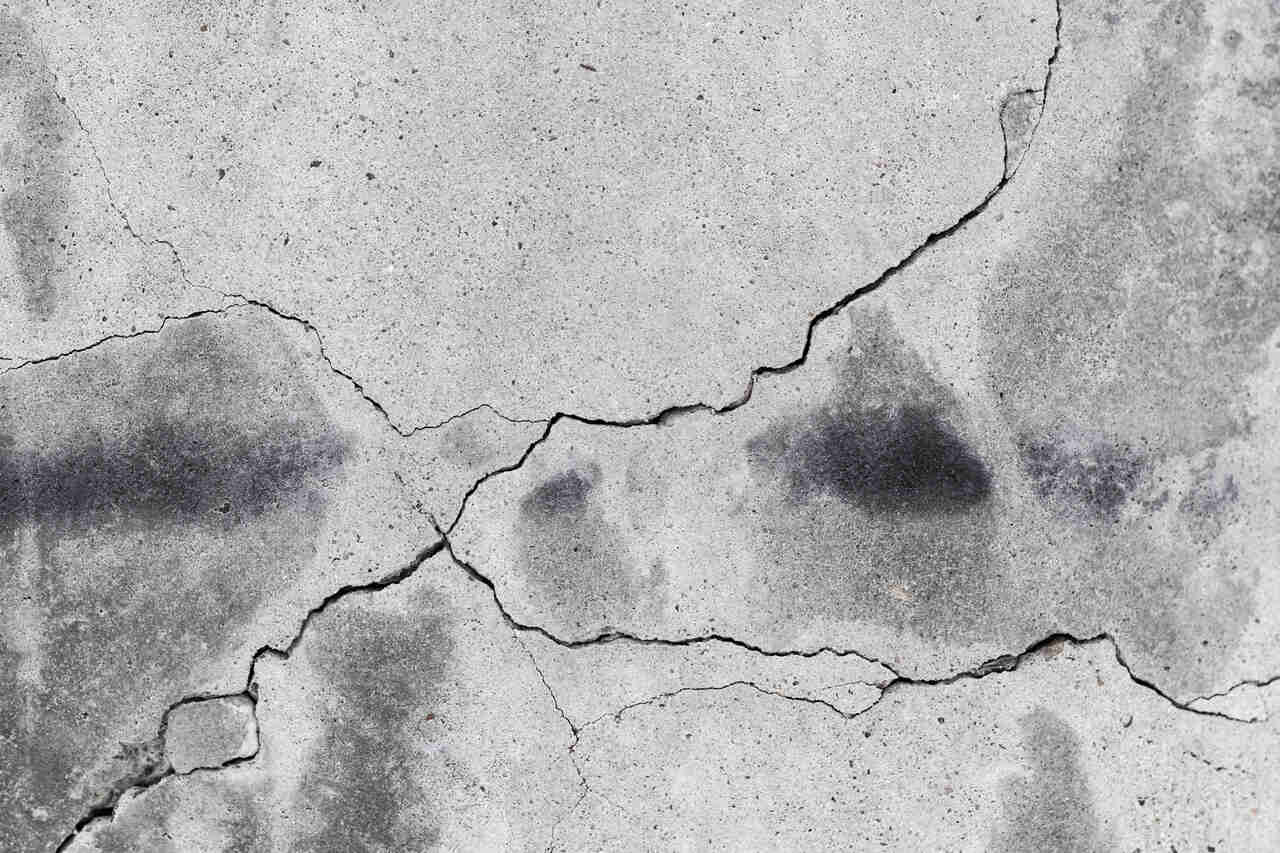

Shrinkage affects both the structural integrity and surface performance of concrete. Cracks that appear on the surface negatively impact both aesthetics and durability. Shrinkage, which results from moisture loss, leads to micro and macro cracking. Shrinkage in concrete may occur in various forms.

What Are the Types of Shrinkage?

Shrinkage types vary depending on the conditions under which moisture loss occurs in the concrete. Shrinkage may appear at different stages or as a result of external influences. The general types of shrinkage include:

-

Plastic Shrinkage: Occurs before setting (hydration), when moisture evaporates rapidly from fresh concrete. This typically happens in hot, dry, and windy conditions.

-

Chemical Shrinkage (Autogenous Shrinkage): Volume reduction that occurs due to the chemical reaction between cement and water during hydration.

-

Thermal Shrinkage: Caused by the expansion due to heat generated during hydration and subsequent contraction as the concrete cools.

-

Drying Shrinkage: Happens after hydration and hardening, due to the evaporation of free water. Unlike chemical shrinkage, this involves moisture moving outward from the concrete.

-

Carbonation Shrinkage: Caused by a reaction between carbon dioxide in the atmosphere and calcium hydroxide in concrete, leading to chemical changes and volume reduction. It is commonly seen in unprotected concrete exposed to outdoor conditions.

So, what do cracks resulting from shrinkage indicate, and how do they form? Let’s explore in detail.

What Is a Shrinkage Crack in Concrete?

As concrete loses volume, tensile stresses develop internally. If these stresses exceed the concrete’s tensile strength, visible shrinkage cracks appear. Since concrete has low tensile strength, it cannot withstand the volumetric contraction and begins to crack. Shrinkage cracks pose both aesthetic and structural concerns.

These cracks typically occur between 30 minutes and 5 hours after the concrete is placed in formwork. They can reach depths of around 10 cm and lengths up to 3 meters.

How Do Shrinkage Cracks Form?

Shrinkage cracks occur due to tensile stress from volumetric contraction in the concrete. As the surface loses moisture through evaporation, shrinkage begins, eventually leading to cracking. The process can be described in the following steps:

-

Fresh concrete is placed in the formwork,

-

Evaporation starts on the surface due to low humidity, wind, and temperature,

-

Water loss during cement hydration results in shrinkage,

-

As the concrete attempts to contract, restraint from the mold, reinforcement, or structural boundaries leads to internal stress buildup,

-

Accumulated tensile stress causes cracks on the surface,

-

These cracks develop parallel to the surface and may deepen, reaching the reinforcement,

-

On exposed surfaces, such cracks may lead to reinforcement corrosion due to water and chemical ingress.

Shrinkage cracks, which harm both the durability and visual quality of concrete, are preventable. So, what steps should be taken to avoid them?

How to Prevent Shrinkage Cracks in Concrete

There are several ways to prevent shrinkage cracks. The following steps should be taken to minimize the risk:

-

Avoid unnecessary cement usage,

-

Use properly graded and fine cement,

-

Keep the water-cement ratio as low as possible—excess water or cement leads to shrinkage,

-

Increase the proportion of coarse aggregates in the mix and choose high-quality aggregates,

-

Ensure proper placement and compaction of the concrete to minimize air voids,

-

Keep the surface moist for the first two weeks after pouring. This prevents rapid moisture loss and significantly reduces shrinkage risk.

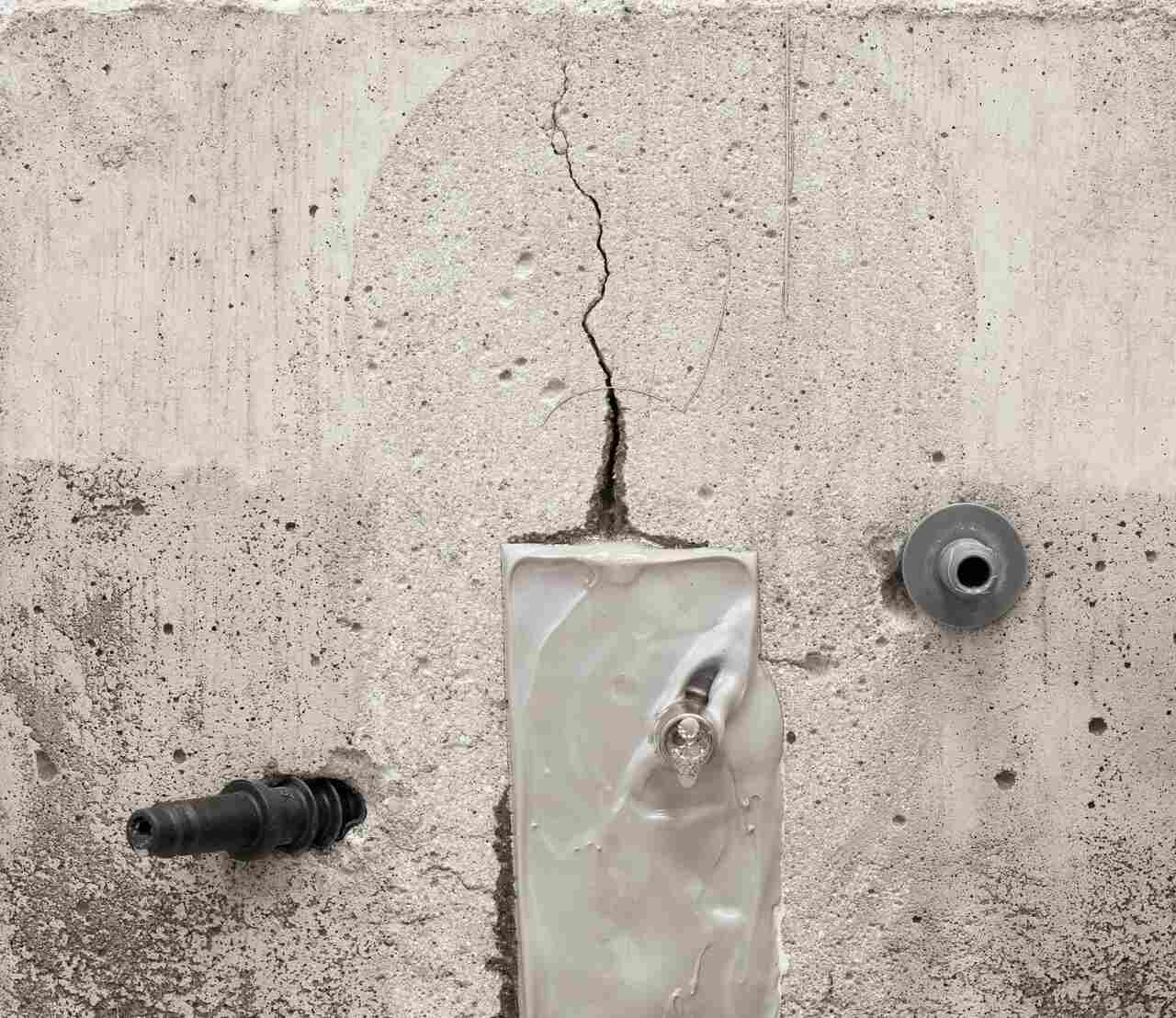

To repair existing shrinkage cracks, first clean the cracks thoroughly and fill them using repair mortars. Baumerk offers a range of compatible Repair and Reinforcement Systems that you can choose from based on the concrete type.

For deeper cracks, epoxy or polyurethane-based materials may be used. In addition to structural repairs, you can also use FIBER – Fiber Reinforced Concrete Additive, which improves crack control and provides tensile strength. Its water-insoluble property enhances abrasion resistance quickly and effectively. After analyzing the cause of the cracks, select a suitable product for the issue.

For the most effective solutions against shrinkage cracks, browse our range of products or get in touch with our expert team today.

We’ve answered the key questions: What is a shrinkage crack, how does it form, and what precautions should be taken? For more insights into construction chemicals and practical solutions, visit our blog page and learn more.