One of the key waterproofing methods, liquid-applied waterproofing involves the application of various membrane materials in liquid form. Reliable and long-lasting solutions are essential in construction when it comes to water insulation. In this regard, liquid-applied materials ensure a watertight seal and protect the structure.

So, what exactly is liquid-applied waterproofing, what does it do, and how is it applied? As Construction Chemicals Experts at Baumerk, we’ve answered your most frequently asked questions.

What Does Liquid-Applied Waterproofing Mean?

Liquid-applied waterproofing is a method used for both water and moisture protection. In this technique, waterproofing materials are applied directly to the outer surface of the structure. A durable coating layer is then added over it. The system helps maintain temperature control and water resistance within the building.

Waterproofing products come in various forms depending on the insulation needs. Generally, the types of liquid-applied waterproofing are as follows:

-

Cement-Based Liquid-Applied Waterproofing

Cementitious coatings are commonly used on both interior and exterior surfaces, particularly in basements and water tanks. They are easy to apply and breathable, making them compatible with concrete surfaces. These materials provide strong water resistance while allowing vapor diffusion. Cement-based waterproofing products can be applied easily to many types of surfaces.

-

Bitumen-Based Liquid-Applied Waterproofing

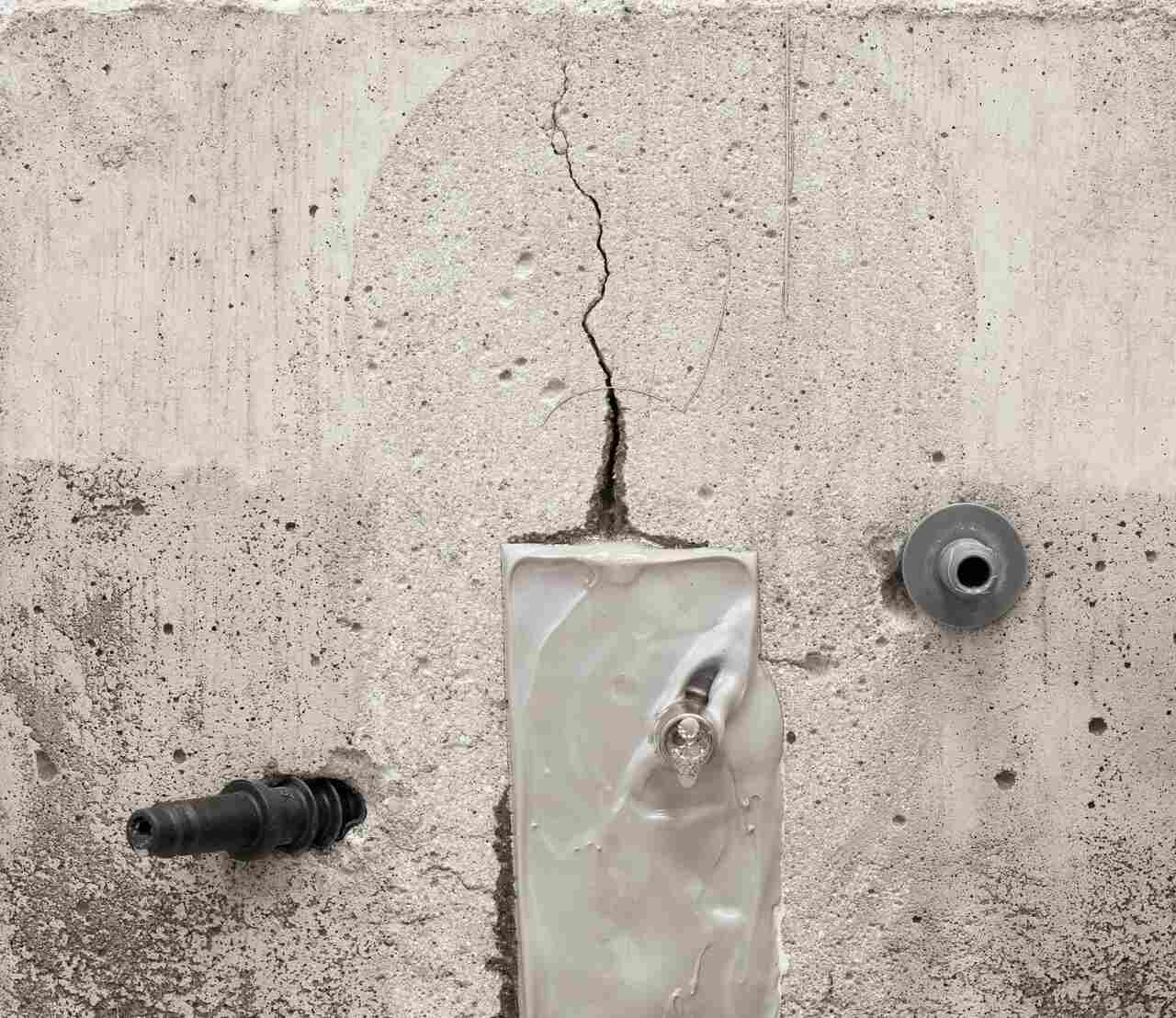

Bituminous coatings, with their flexible structure, offer crack-bridging capabilities and are mostly used on dynamic surfaces. They perform well against water in underground structures like foundations and retaining walls. These systems are usually applied with a primer to ensure strong adhesion to the substrate.

For more information, visit our Bitumen-Rubber Based Waterproofing Products page.

-

Polyurethane Liquid-Applied Waterproofing

Polyurethane-based membranes offer high elasticity and chemical resistance. They are ideal for long-lasting waterproofing in open areas such as terraces, roofs, and balconies. Once cured, they form a flexible membrane that helps prevent cracking.

-

Two-Component Fluid-Applied Waterproofing

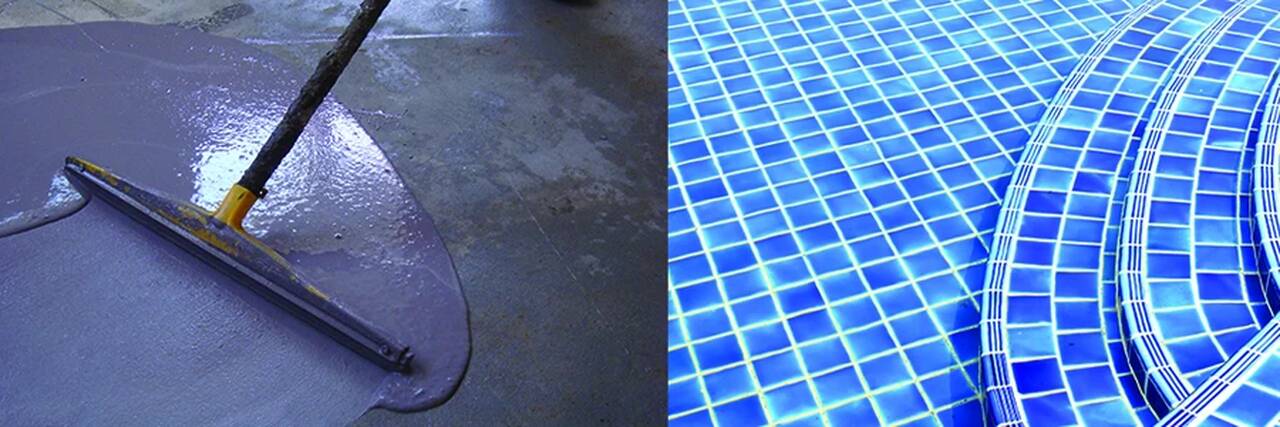

These systems cure through a chemical reaction and provide a combination of waterproofing and flexibility. They are suitable for areas exposed to constant moisture, such as pools and wet-area floors. These fluid-applied systems offer high durability and excellent mechanical performance.

Liquid-applied waterproofing products may be cement-based, single-component crystalline, cement-acrylic, polyurethane-based, or bitumen-based. These materials are applied to surfaces using brushes, rollers, or trowels. For example, CHIMEX 127 – Cement-Acrylic Waterproofing Material is a highly effective liquid-applied product that can be applied easily by brush.

What Does Liquid-Applied Waterproofing Do?

Liquid membranes help regulate indoor temperature and block water ingress. Applied with various material types, this method reduces moisture and humidity levels on surfaces, enhancing indoor comfort. In general, a liquid-applied waterproofing system performs the following functions:

- Regulates the indoor temperature of the building, offering a more comfortable living space.

- Enables fast and easy insulation without altering the building’s exterior appearance.

- Prevents water and moisture damage in wet zones — thereby avoiding mold, dampness, and freeze-related deterioration.

- Can be applied using brushes, rollers, or trowels — an economical method that requires no special equipment.

- Offers strong chemical and mechanical resistance, making it suitable for extreme weather and temperature fluctuations.

- Ensures full coverage even in corners, joints, and complex surface geometries.

Both single-and two-component liquid/fluid-applied systems enhance the durability of a structure. Applied with brushes, rollers, or sprays, these membranes contribute to the long-term resilience of buildings.

Where is Liquid-Applied Waterproofing Used?

Liquid-applied waterproofing can be used across a wide range of applications. As part of comprehensive waterproofing strategies, this method is suitable for roofs, walls, and floors. Main application areas include:

- Buildings: Applied to roofs, terraces, walls, and floors of homes, offices, shops, workshops, and public buildings.

- Industrial Structures: Suitable for factories, warehouses, and areas with mechanical vibrations.

- Water Tanks: Specialized versions are used in potable water tanks, offering critical hygiene and leak prevention.

- Foundation Waterproofing: Applied after concrete is poured to prevent water from entering from inside or outside.

- Swimming Pools: Used to block water pressure and leakage in pool structures.

Liquid-applied systems are also used to combat moisture and dampness. The specific application depends on the structure's unique features and needs.

How is Liquid-Applied Waterproofing Applied?

This method follows standard steps common in waterproofing applications. Using appropriate materials, the liquid membrane is applied via brush, roller, or spray. The general process includes:

- Clean the surface thoroughly (remove dust, oil, and residues).

- Mix the product according to instructions.

- Apply the first coat with a brush or roller.

- Once fully dry, apply the second coat.

- Wait for the final curing.

Drying time usually ranges from 4 to 12 hours. Full curing may take over 24 hours. If additional finishing layers will be applied, it is best to wait at least 3 days. With Baumerk’s quality liquid-applied systems, your building will enjoy long-lasting protection against water infiltration.