One of the applications used in crack repair of structures is epoxy injection. This application both increases the safety of the structure and ensures an aesthetic appearance. Depending on the size and depth of the crack, how epoxy injection should be applied may differ.

As Baumerk, we have listed step by step how epoxy injection is applied and what is wondered about this subject!

What is Epoxy Injection?

Epoxy injection is used for the repair of vertical and horizontal cracks in beams and columns, especially in concrete structures. This method is injected into the crack under low or high pressure depending on the depth and width of the crack. The voids formed along the crack are completely filled, and the monolithic integrity of the reinforced concrete structure is restored. So, for what purposes is epoxy injection used when we look at its functions?

What is Epoxy Injection Used For?

Epoxy injection application is used in the repair of cracks in reinforced concrete beams, columns, shear walls, and slabs. Basically, there are two purposes in applying this method:

-

Preventing water, moisture, and air permeability,

-

Repairing structural load-bearing capacity and integrity.

When we look at the functions of epoxy injection, we see that it is used in many areas for crack repair. The detailed answer to the question of what epoxy injection is used for is as follows:

-

Increases the load-bearing capacity of the structure by filling micro and macro cracks,

-

Restores the integrity between cracked concrete elements,

-

Prevents the risk of corrosion by cutting off the reinforcement’s connection with moisture,

-

Repairs cracks after earthquakes and is used in building strengthening,

-

Supports waterproofing applied in areas such as basements, shear walls, and parking lots.

Now let’s move on to detailed information on how this effective method is applied.

Step by Step How is Epoxy Injection Applied?

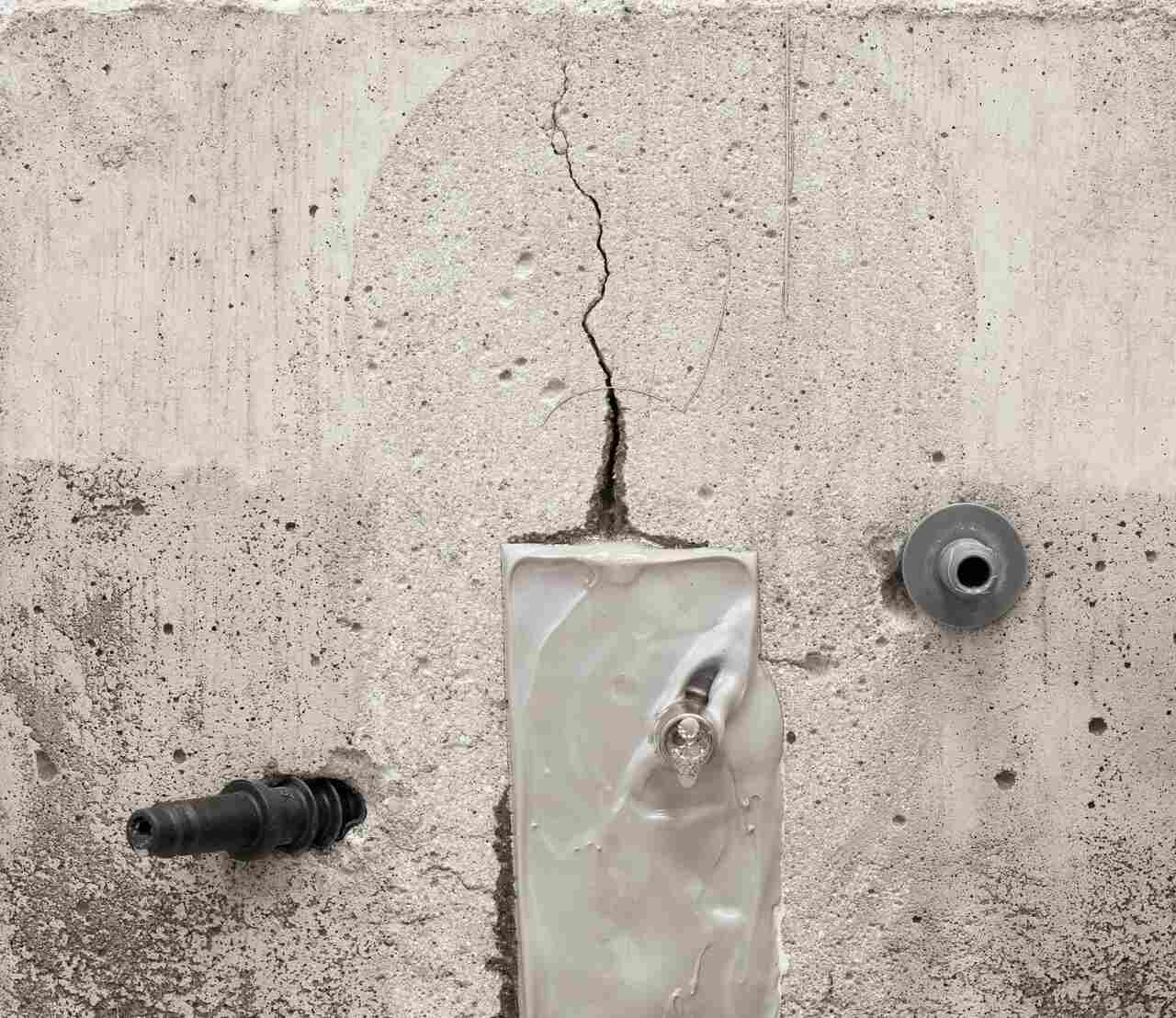

It is possible to repair cracks and prevent moisture with epoxy injection. After determining why the crack occurred, surface preparation is carried out. In the epoxy injection method, the following steps are applied in order:

-

First, the surface to be applied must be cleaned of dust, dirt, and oil,

-

After the cracks are identified, holes are drilled at certain intervals for the injection ports,

-

While drilling, steps are taken according to the length and depth of the crack,

-

Then injection ports are placed in the drilled holes and epoxy putty is applied around them,

-

To increase surface tightness, the surface along the crack line between the injection ports is sealed with epoxy putty,

-

Epoxy resin is prepared and mixed until homogeneous according to the manufacturer’s instructions,

-

The prepared epoxy mixture is injected into the crack with appropriate pressure,

-

After the injection is completed, the ports are removed and epoxy residues on the surface are cleaned. If necessary, the surface is sanded to make it smooth.

It is also very important to select the epoxy-based materials used in all these processes correctly. At this stage, it is necessary to determine why the crack occurred and why crack repair is being carried out. For example, if crack repair will be carried out for building strengthening, Strengthening-Based Epoxy Injection System - EPOX IN 25 specially produced for this purpose can be used. Again, for epoxy to be applied to the concrete surface, Concrete Injection System - PUR IN 24 can be applied. In addition, there are points to be considered during the application and maintenance stage.

What Should Be Considered During Epoxy Injection?

It is also necessary to act very meticulously in epoxy injection application. For the desired structural durability and tightness, correct material selection and correct application steps are essential. The points to be considered during the application stage can be listed as follows:

Crack Analysis

It should be evaluated by an expert team whether the crack is superficial or of a nature that will damage the load-bearing system.

Proper Surface Preparation

The application area must be cleaned of dust, oil, moisture, and loose particles. Because contamination on the surface negatively affects the adhesion strength of the epoxy resin.

Correct Mixture

The A and B components of the epoxy resin must be mixed in the correct ratio and homogenized according to the manufacturer’s technical datasheet. Applications made with incorrect ratios prevent the resin from hardening.

Suitable Pressure and Temperature Setting

The pressure to be used during injection should be determined according to the crack width. The ambient temperature must be within the applicable range of the epoxy product.

Proper Timing

Epoxy must be used within a certain period after mixing its A and B components. This period is called “pot life” and is usually in the range of 20–40 minutes. When the period is exceeded, epoxy begins to harden, loses its fluidity, and cannot penetrate the cracks. Therefore, the mixture must be prepared considering the application time.

In general, you can make a durable crack repair by paying attention to these steps and maintenance controls. Together with crack repair, you can also choose Baumerk’s Maintenance and Repair Systems products for other materials used in the repair-strengthening process with Baumerk assurance.