Although concrete is a strong construction material, under certain conditions it can become a sensitive material. Pouring concrete in cold weather, in particular, requires taking several precautions. To ensure durability and long service life, it is essential to comply with the conditions of cold weather concreting and take the necessary measures.

So, how should concrete be poured in cold weather, and what should be considered? As Baumerk Construction Chemicals Experts, we have answered these questions!

Why is Cold Weather Concrete Pouring Risky?

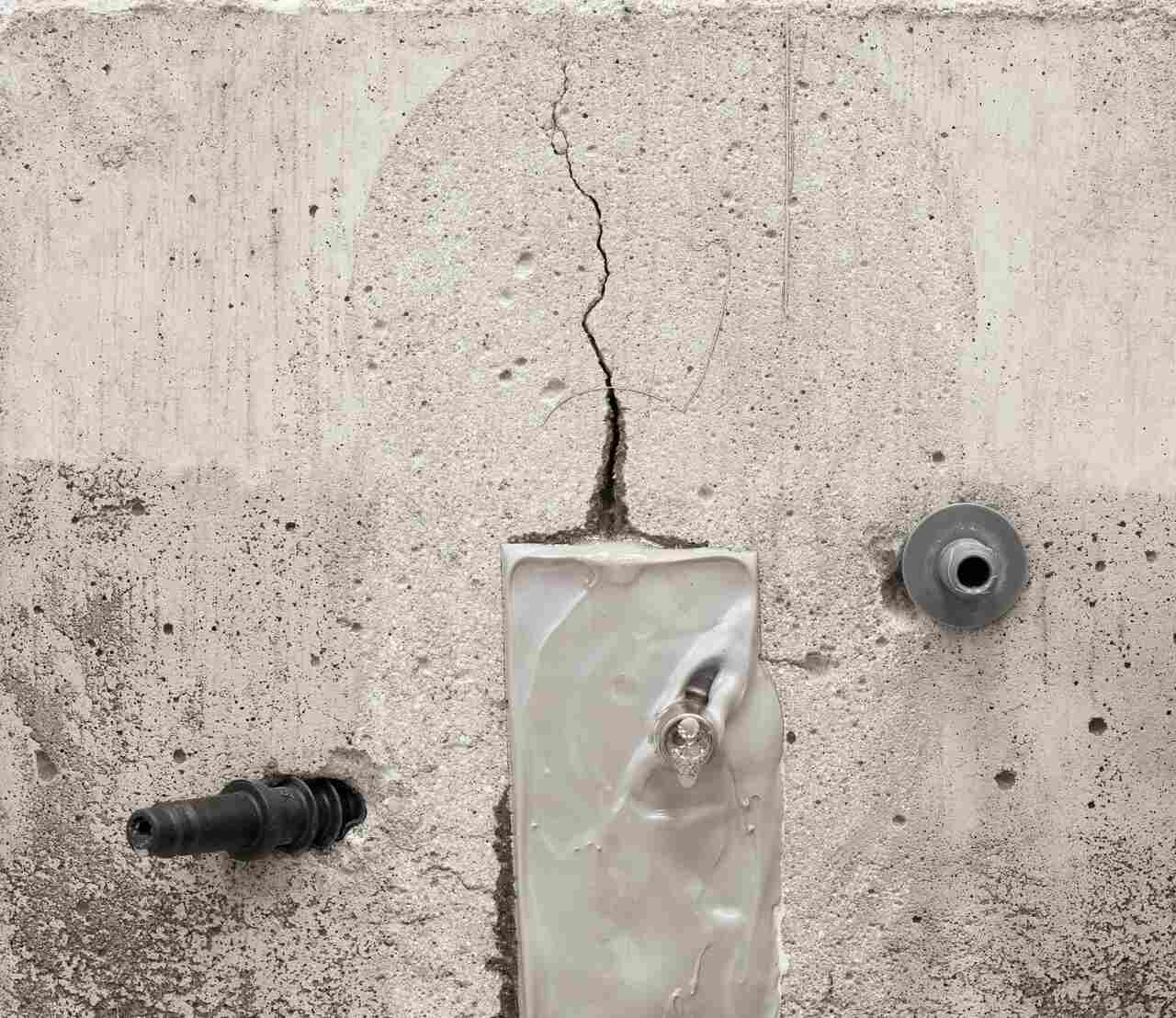

In cold weather, significant temperature differences occur between the internal temperature and the surface temperature of the concrete. In such cases, stresses, cracks, and problems caused by the expansion of frozen water may occur. In general, pouring concrete in cold weather significantly reduces the strength and durability of concrete. Therefore, knowing how to pour concrete in cold weather is crucial.

Conditions for Cold Weather Concrete Pouring

Just like in hot weather, it is important to know the conditions for concrete pouring in cold weather. According to Turkish Standards, specific rules must be followed when pouring concrete in cold weather. The relevant standard in this context is TS 1248, which outlines the Rules for Concrete Preparation, Pouring, and Curing under Abnormal Weather Conditions.

This standard requires careful monitoring of each step from concrete production to the curing phase, and taking necessary precautions against the risk of freezing during the setting process. According to TS 1248 – Rules for Concrete Preparation, Pouring, and Curing under Abnormal Weather Conditions:

Definition of Cold Weather: Cold weather refers to situations where the highest daytime temperature for three consecutive days drops to 5°C or below.

Material Temperatures: The concrete components (especially water and aggregates) must be kept above their freezing point. If necessary, mixing water and aggregates should be heated.

Mixing Temperature: The temperature of fresh concrete during pouring should be between +5°C and +10°C, depending on the concrete class and the thickness of the structural element.

Admixtures: Suitable chemical admixtures (accelerators or antifreeze admixtures) should be used to counter the risk of freezing.

Formwork and Reinforcement Protection: Formwork surfaces should be cleaned of ice and snow before contact with concrete. If the reinforcement steel is frozen, it should be thawed.

Placement and Compaction: The pouring process should be fast and continuous. The concrete must be properly compacted to avoid any voids.

Curing Procedures: After pouring, the concrete surfaces should be protected with covers, insulation boards, or heating systems to prevent heat loss. During the curing process, the temperature should be maintained at a level that allows the concrete to complete its setting process.

Sudden Temperature Changes: After the concrete has set, cooling should be done gradually, and it should not be exposed to sudden cooling.

The above points cover the planning of concrete preparation, transportation, pouring, and curing in cold weather. Paying attention to these aspects, particularly preventing the risk of freezing, is essential.

Temperature Values for Concrete Pouring in Cold Weather

The initial temperature of the concrete is also an important factor under cold weather conditions. The concrete’s starting temperature varies depending on the surrounding ambient temperature and the thickness of the concrete mass. According to TS 1248, the recommended temperature values are as follows:

-

For thin elements (<300 mm): Concrete temperature should be at least 13°C

-

For medium-thick elements (≥300, <900 mm): Concrete temperature should be at least 10°C

-

For thick elements (≥900, ≤1800 mm): Concrete temperature should be at least 7°C

-

For very thick elements (>1800 mm): Concrete temperature should be at least 5°C

These temperature values reflect the minimum temperatures that concrete should maintain during pouring and the protection period. Additionally, there are recommended minimum concrete temperature values based on ambient air temperature, as per the same standard. These values are as follows:

-

If the air temperature is greater than 1°C: Concrete temperature should be between 7°C and 16°C

-

If the air temperature is between -1°C and -18°C: Concrete temperature should be between 10°C and 18°C

-

If the air temperature is below -18°C: Concrete temperature should be between 13°C and 21°C

In addition to the temperature values to be observed during concrete pouring, it is essential to know the precautions against freezing hazards.

Precautions for Cold Weather Concrete Pouring

Concrete pouring is a highly risky application when frost effects last for days. In such cases, precautions are required to protect the concrete against cold weather and the risk of frost. Cold weather concrete casting antifreeze solution is one of these measures. The frost preventive liquid admixture Concrete Antifreeze PROGEL-10 increases the strength of concrete against cold weather. With its chloride-free composition, it can also be used safely. Other recommended measures and uses are as follows:

-

Suitable insulation and formwork materials must be applied with the correct curing method to protect the concrete,

-

After casting, the surface must be covered with appropriate insulation sheets (such as felt, styrofoam, blanket-type insulation products) or heated formwork systems,

-

To ensure waterproofing of concrete, products such as Liquid Concrete Admixture with Crystallizing Effect CRYSTAL C 320 should be used,

-

Formwork should be assembled before freezing occurs and, if necessary, pre-heated,

-

During and after casting, the temperature of the concrete should not fall below 5°C. Therefore, hot mixing water should be used and aggregates should be heated before freezing,

-

Since metal formwork conducts cold, wooden or thermally insulated formwork is preferable,

-

If possible, casting should be carried out during the warmer hours of the day, as daytime temperatures are higher,

-

For slab and floor concretes, low-viscosity curing compounds should be used to reduce bleeding and shorten the setting process,

-

Finishing operations must never be carried out before bleeding has ended or while bleed water remains on the concrete surface.

The above precautions accelerate the setting process of the concrete. In this way, the strength of the concrete increases, and the desired casting process can be completed smoothly. In our article, we answered the question of how to cast concrete in cold weather. For details on all admixtures used on concrete surfaces, you can also check out our article “What is Concrete and What is in It?” to access accurate and up-to-date information on such topics, feel free to visit our other content as well.