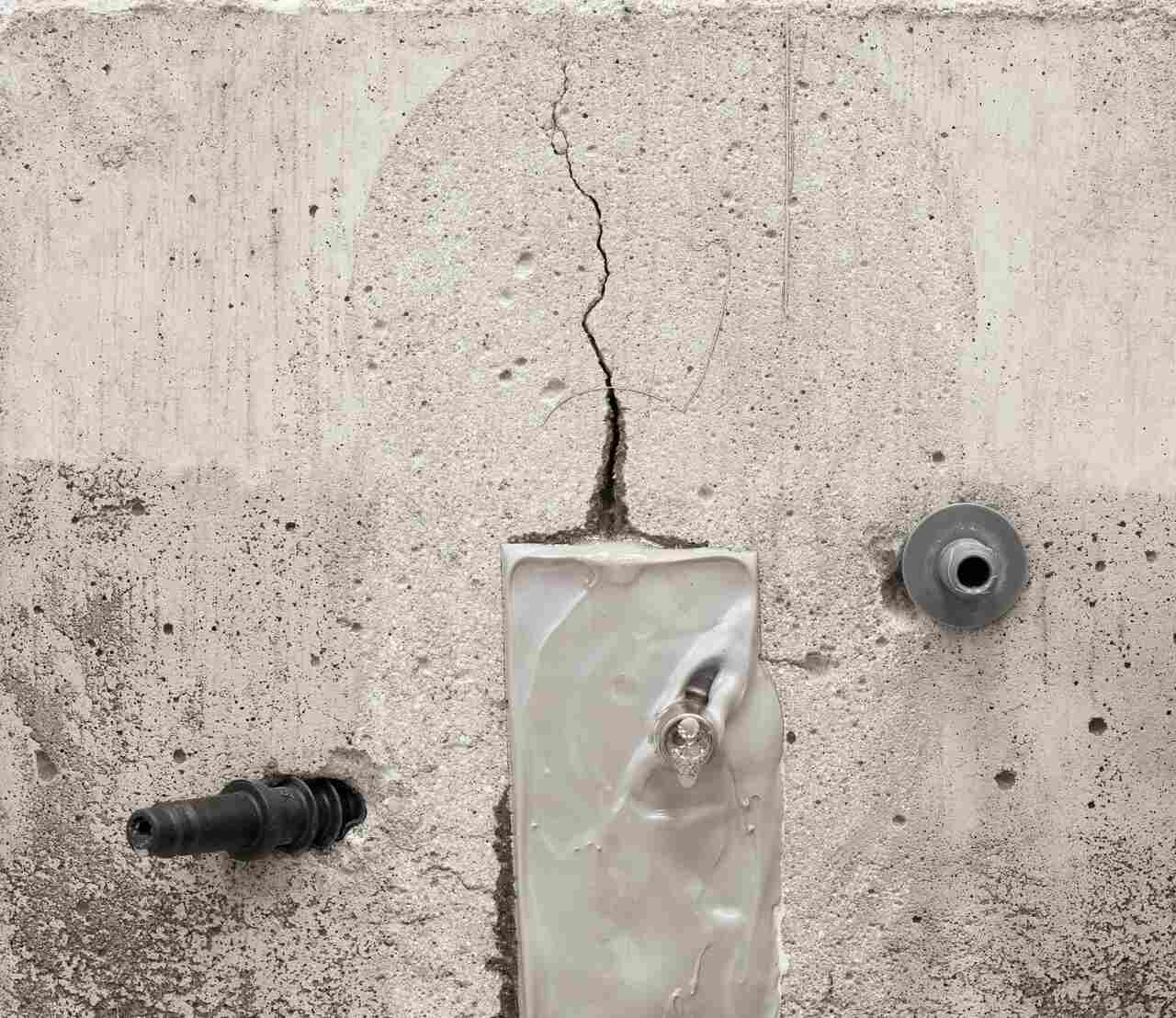

Storage of drinking water is a very important issue for human health. Since water is the most basic need of living things, it is very important to keep the stored water pure and clean. In a drinking water tank with incomplete water tank insulation, water leaks into the tank due to groundwater pressure. When a crack occurs, groundwater and soluble salts will leak into the tank and cause structural damage.

In addition to this, another problem is the start of fungal growth with leaking water. Water should be protected from such formations for human health. Therefore, water tanks need waterproofing both from the outer surface and inside the tank.

For water tank waterproofing, appropriate materials should be used considering the pH value, mineral content, temperature and water cleaning chemicals to be used. Apart from the waterproofing of these insulation materials, it is also necessary that they are not dangerous for human health in contact with water. For this, especially materials suitable for use in drinking water tanks should be selected.

As Baumerk, a construction chemicals specialist, we will talk about water tank waterproofing in this article.

Why is Water Tank Waterproofing Important?

-

Prevents the water from heating up: In an uninsulated tank, the sun's rays and ambient temperature cause the water to heat up. Bacteria and algae formation accelerates in heated water. This situation threatens human health by deteriorating the color, smell and taste of water.

-

It prevents the water from cooling: There is a risk of water freezing in uninsulated tanks in winter. As a result of freezing, cracks may form in the tank, which can lead to water leaks.

-

Extends the life of the tank: Insulation extends the life of the tank by preventing it from being affected by temperature changes.

-

Saves energy: Insulated tanks prevent water from heating or cooling, which saves energy used for water heating and cooling.

What Qualities are Required in Water Tank Insulation Materials?

Drinking water must be protected in clean and watertight facilities with excellent processing and storage. Specially designed drinking water reservoirs and tanks are used for this purpose. These tanks must be watertight, clean, safe, and harmless to health.

Waterproofing materials for drinking water tanks are materials that meet the following characteristics:

-

Resistant to hydrostatic pressure

-

High mineral resistance

-

Resistant to cleaning agents

-

Corrosion resistant

-

Prevents algae and moss formation

-

Free of harmful substances for human health

Products Used in Water Tank Waterproofing

Selection of water tank insulation material to be used in the water tank should be made according to these factors:

-

Type of tank (concrete, metal, plastic, etc.)

-

The size of the tank

-

Purpose of use (drinking water, domestic water, etc.)

-

Climate of the region

-

Budget

Some commonly used water tank insulation material products are as follows:

1. Surface Coating Products

Bitumen-based products: One of the most widely used waterproofing products in water tanks. It can be applied in liquid or solid form.

Synthetic resin based products: More elastic and durable than bitumen-based products.

Polyurethane (PU) based products: They have high waterproofing capacity, are lightweight and easy to use.

2. Crystallized Waterproofing Products

CRYSTAL 25, CRYSTAL PW 2, and CRYSTAL C 320, specially produced by Baumerk, are products that clog the pores of concrete and form a waterproof layer by entering into a chemical reaction when in contact with water. They provide permanent waterproofing by filling all cracks and gaps where water can seep in. They are easy to use and long-lasting.

How to Waterproof Water Tanks?

Generally, water tank insulation is completed with the following steps in order:

1. Application of Primer Material

The water tank is applied with a water-based, epoxy-based primer material that can be applied to damp surfaces and applied to all surfaces with a single layer brush or roller. Baumerk's solvent-free and chemical-resistant EPOX PR 300, which can be applied to horizontal and vertical areas, is one of the most suitable options for interior surfaces.

2. Insulation of Pipes

A polyurethane-based, moisture-curing sealant with high mechanical strength is used to insulate details such as pipes in the tank. Baumerk's PUMAST 600, which cures with moisture in the air and does not require primer before application, can be used safely on pipes in the tank.

3. Application of Joint Tapes

All corners of the tank are chamfered with elastic joint sealing tape. Baumerk's PH 127, which has high water and thermal resistance, has the ability to maintain its elasticity in temperature differences and is an easy-to-apply option.

4. Application of Insulation Material

The first coat is applied with a polyurethane-based, solvent-free coating material suitable for use in drinking tanks. Baumerk's POLIXA 2 has high adherence, is resistant to abrasion and impacts and is harmless to health; it can be used safely at this stage. Alkali-resistant insulation mesh is laid on all surfaces before the first layer of coating material dries. The topcoat is applied and the tank is left to cure. Since POLIXA 2 does not contain solvents, it can be used safely at this stage as well.

To learn more about waterproofing materials, you can take a look at our content titled What are the Waterproofing Materials?: All Types, Uses and Features

Proper insulation of drinking water tanks ensures that the quality of the water is maintained and the installation works in a healthy way. Therefore, water tank insulation should not be neglected and should be checked regularly. Baumerk's materials specially developed for water tank insulation have been successfully approved in tests for suitability for drinking water. You can take a look at Baumerk products such as waterproofing membranes and construction chemicals for water tank insulation!